Management History

1966

FOUNDED BY RENÉ CREVOISIER

Our company’s founder, René Crevoisier, was an ingenious inventor who revolutionised his field of expertise. With a passion for innovation and research, he created products which have changed people’s lives. Thanks to his relentless work and perseverance, he was able to make his innovative ideas count, and transform them into real achievements. His visionary spirit has enabled our company to prosper and become a leader in its sector. We are proud to perpetuate his heritage by continuing our quest for innovative solutions to meet the needs of our customers.

1977

PHILIPPE CREVOISIER, COB

Philippe joined the company as an apprentice, before going on to complete the training he needed to develop the business. In 1990, he was appointed Mechanical Workshop Manager. Then in 1992 he became a company shareholder and a Board Member with individual signing authority. In 1998, he became the CEO. His dynamism, perseverance and solidarity have been a driving force behind the company’s success. Philippe always makes it a point of honour to be accessible to his staff and to listen to them. He is keen to maintain the friendly, family spirit of the business. In 2025, he passed on the company to his son Laurent, and became Chairman of the Board.

2000

nicolas ramseyer COO

Nicolas joined the company in 2000 as the Mechanical Workshop Manager. Then in 2002, he was appointed COO. His new approach, particularly in terms of workflows and departmental organisation, has enabled the company to improve process reliability and to look ahead to new challenges.

2019

LAURENT CREVOISIER CEO

In 2019, Laurent joined the team as Project Manager. The new department he has set up is helping the company to improve our customer relations by means of project tracking from order through to delivery, with a single point of contact. In 2023, he was appointed Deputy CEO. This appointment marked a significant moment, with a third generation of the Crevoisier family taking the reins of our company since its foundation. In 2025, he succeeded his father Philippe to become CEO.

INVENTIONS HISTORY

1966

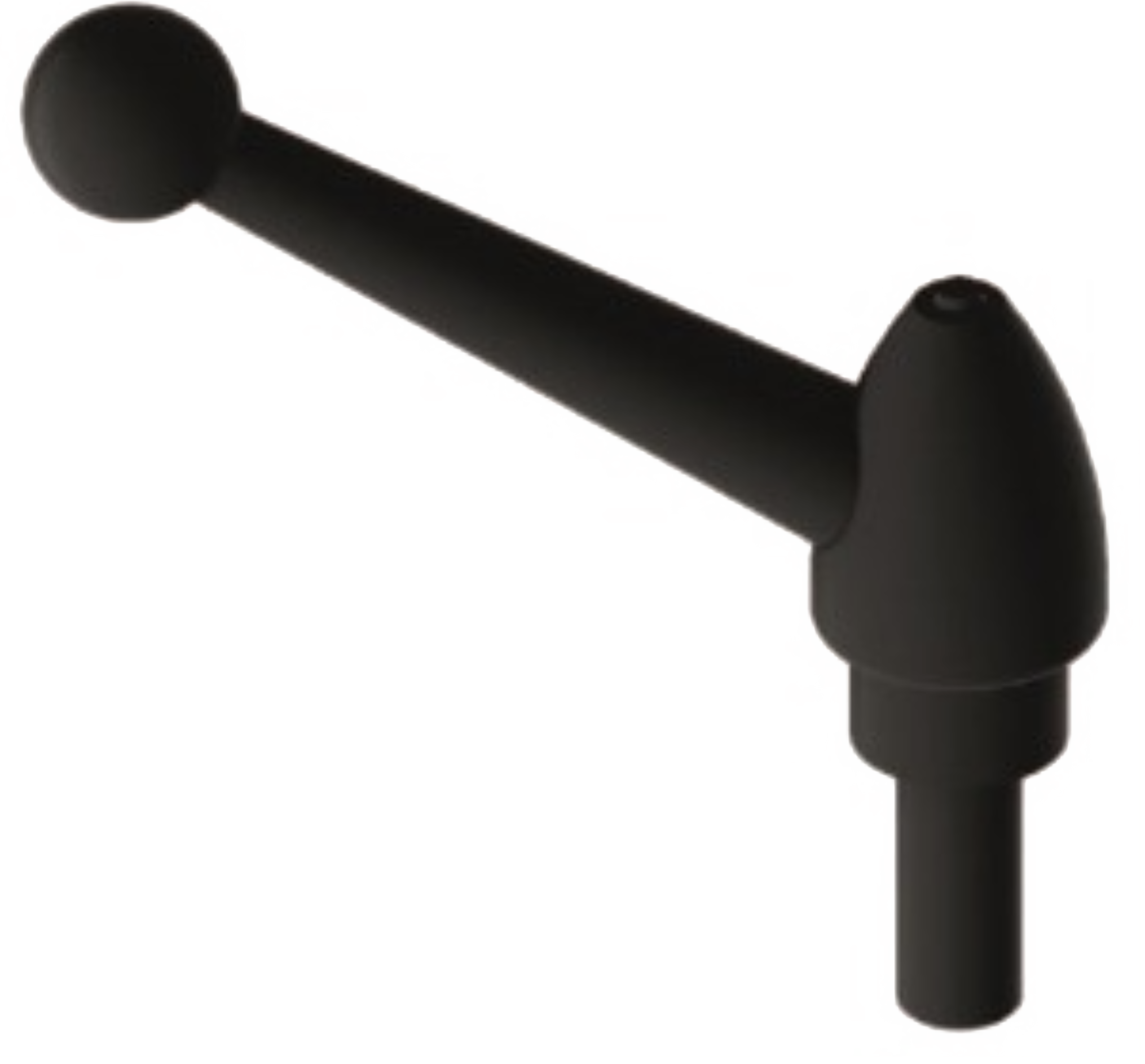

First Invention

The clamping handle, one of our founder's first inventions, is an innovative solution which has revolutionised the mechanical fastening world. This clamping handle was designed to provide a quicker and more practical alternative to traditional clamping methods. It is easy to use, and is adaptable to a wide variety of applications. This invention has been adopted worldwide, becoming an essential tool and inspiring a host of different versions. The clamping handle remains an iconic example of the ingenuity and vision of our founder.

1974

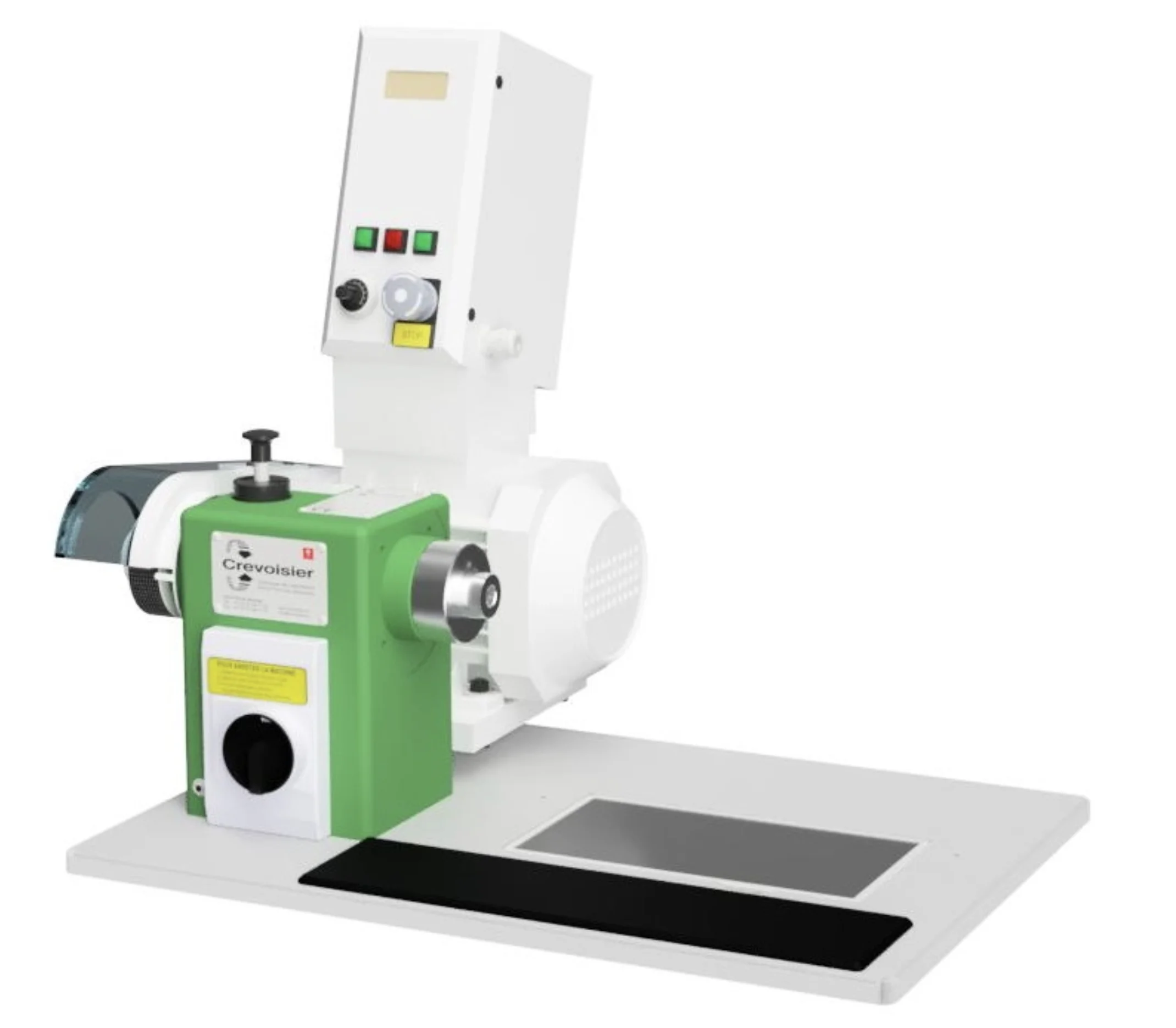

First Polishing Machine

The C501 machine and its accessories are a major innovation in the field of polishing. This machine was specially designed to provide a quick, efficient and easy-to-use solution for polishing professionals. Thanks to its advanced features, the C501 is able to perform high-quality polishing in record time. It is equipped with accessories such as belt devices, lapping machines, tables and various clamps, to ensure excellent polishing performance. This innovation has revolutionised the everyday job of polishers, by providing a quicker, safer and more efficient solution to achieve professional results. The C501 has become an essential tool for polishing professionals, and we have distributed more than 6000 units across 65 countries worldwide.

1992

Establishment of the Anonymous Company CREVOISIER SA

The creation of the public limited company was a crucial step in the continuation of our growth, the same as the expansion of the building.

2004

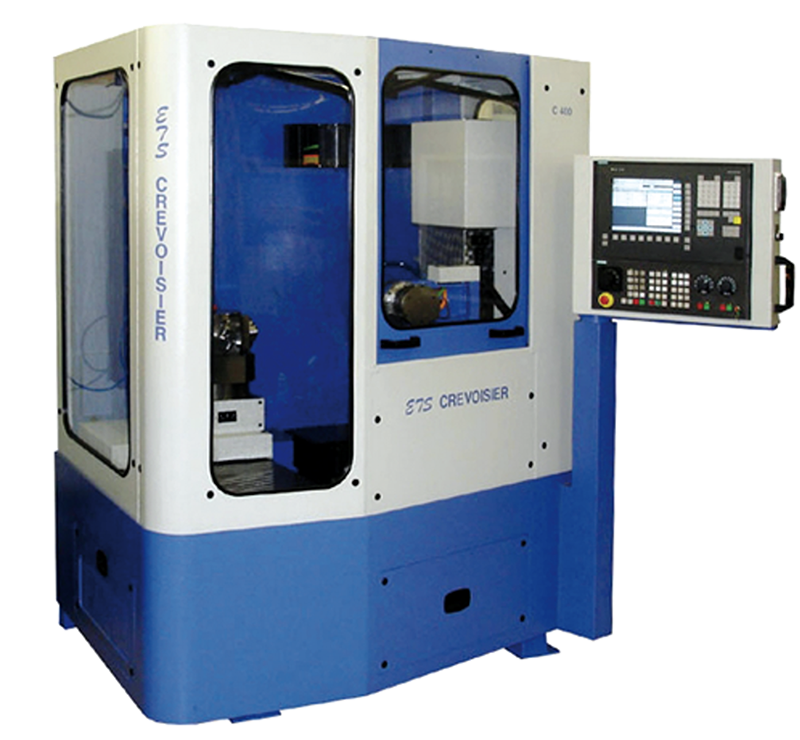

First Machine C400

In 2004, our company reached a major turning point with the creation of the first CNC C400 machines. This technology paved the way to a new adventure for us and our customers, in search of larger-scale production equipment to meet the growth of their markets. With the C400 CNC machines, our customers have been able to increase their production capacity, achieve greater operating precision and efficiency, with shorter lead times. Today, our machines derived from the C400 range have become essential to our business, and we are continuing to integrate new features to meet current needs. We are proud of this success and maintain the conviction that this has helped us strengthen our position as number one on the finishing machines market.

2005

Robot de chargement C60

Équipé d’un bras robot polyarticulé 6axes et d’un palettiseur, il intègre une technologie de vision. Avec cette solution, nos machines travaillent en complète autonomie 24h/24 7j/7.

2013

1st Prize Innovation EPHJ (Polishing Robot)

In 2013, we took a new step forward in programming the polishing robots, by creating a bobino-based learning system, with built-in motion capture technology. Yet in spite of winning awards for its ingenuity, this innovation did not enable manufacturers to revolutionise their finishing processes, since the investment impeded the roll-out of the technology. However, we are proud to have been at the forefront of this technology and to continue our innovation to meet the needs of our customers. Today our robot programming system for the CREVOISIER® C710 polishing cell is the little brother of this invention, and it is widely used in the industry, having become a key part of our activity. We will continue to develop new technologies, to bring our customers innovative and efficient solutions.

2014

Implementation of Lean Management

Lean management is a management method aimed at optimising the production process, by eliminating waste and maximising added value. To implement this approach, we needed to review the entire organisation and involve all the players in the company. This was achieved by implementing a culture of continuous improvement, simplifying the production flows, training the teams and setting up relevant performance indicators. Hence lean management has improved the quality of our products, cut costs and increased customer satisfaction.

2018

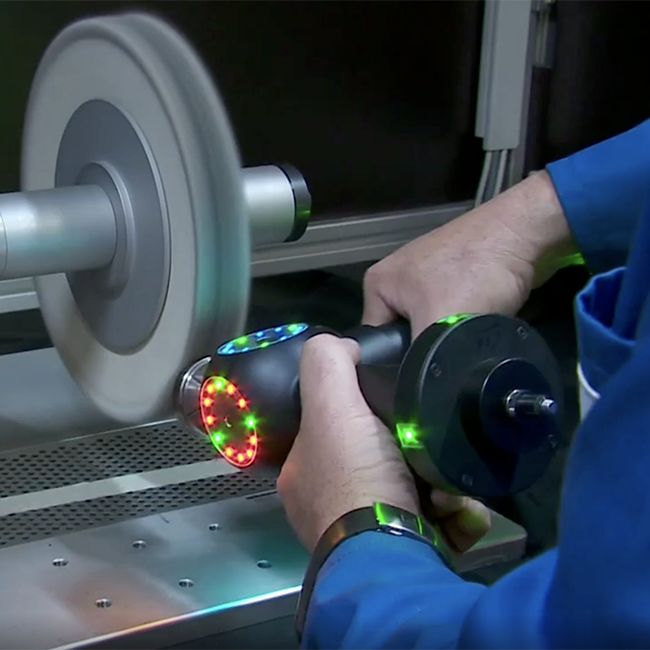

Presentation at EPHJ of the 1st Collaborative Polishing Robot

The invention of this new polishing technology has revolutionised the industry, enabling a significant reduction in CO2 emissions while helping resolve the shortage of qualified polishers. This innovative technology, developed by our engineers, has a built-in robotic arm on a polishing station. These machines are used by polishers for programming trajectories, and entrusting the toughest and most repetitive tasks to the machine The robotic polishing technology also makes it possible to obtain more consistent results in terms of dimensions, and while the machine carries out the preparatory operations, the polishers can focus fully on the high added-value operations. The machines can work 24/7, which considerably increases productivity and reduces lead times. This innovation has enabled the company to strengthen its market leading position. Thanks to this cutting-edge technology, the company can meet the growing demand for highly specialised products, while reducing the environmental impact of our production and creating qualified local jobs.

Watch the video

2019

1st Prize BaselArea + 1st Prize "THE SHAPERS" (CCI Swiss Romande)

Since the company's creation, it has received several prizes in recognition of the work of our teams and our management strategy. Following the release of the C710 polishing robot, the Swiss Romandy Chambers of Commerce bestowed a prize on us for the quality of this invention, and a few months earlier we received awards from the Basel Area regions, the Grand Est region (FR) and Bad Wurtemberg (DE) for our installations on PSA automotive group premises.

2020

New Design and Branding

In our company, the design of our products is an important parameter. We believe that design plays an essential role in creating a high-quality user experience, and we maintain the conviction that this is an integral part of our customers' satisfaction. We also attach great importance to the consistency with our graphic charter, in order to strengthen our brand image and facilitate recognition of our products. We are proud of our design teams' great talents, and that they are constantly working to create ergonomic, aesthetic and functional products, while reflecting our company's visual identity.

2021

Launch of the E-Shop

At the height of COVID, we were able to continue operating due to the creation of our online configurator, which lets our customers from all around the world customise their machine to their specific needs. With this tool, our customers can easily choose the features and options most suitable for them, and receive personalised offers according to their configuration. This configurator offers a simple and efficient way of customising our products and meeting the unique needs of each customer. Although we are convinced that this solution provides a high-quality service to our customers worldwide, while offering a fluid and pleasant experience, we of course are still available for face-to-face discussions with our customers.

Watch the video