Thanks to the work of our team of engineers on the vacuum system, the new range of polishing stations CREVOISIER® DSG2 occupies 17% less floor space, offers an increased flow rate of 20% and reduces overall sound by 6 decibels, thus improving performance and comfort.

Ensure the well-being of your team with this range designed for ergonomic and safe work.

A masterpiece of versatility designed to meet your specific needs. Equipped with autonomous suction, it ensures a clean working environment, while the customizable work table guarantees an optimal ergonomic experience. Adjustable legs and built-in storage drawers add convenient functionality.

Whether you are in a production unit, an after-sales service center or a training school, this position adapts perfectly to your environment.

DSG: personalize every detail, adjust the height, choose the color of the workstation, and adapt the workspace with effective options

Accessories

Customize your polishing station with a variety of accessories, offering multiple options to meet specific needs. These accessories are designed to improve the work of your employees and make the workstation more ergonomic.

Configure your position online and choose your tools.

The C5100 universal finishing machine is used for polishing, sharpening, satin finishing, stone polishing and many other preparation and finishing jobs.

This latest generation machine is equipped with a spindle motor and a touch screen for an intuitive user interface.

This machine is used in production units as well as in after-sales service centers or training schools. Available for installation on a workbench or on a station with integrated suction.

This latest generation machine is equipped with a low energy consumption spindle motor and designed exclusively for consumables mounted on cleats.

The CREVOISIER® cleat changing system allows you to move from one series to another and/or from one operation to another quickly and simply.

This polishing machine has revolutionized the daily lives of polishers who did not hesitate to rename our C501, “the good all-rounder”.

With more than 6,000 units produced and deployed in 65 countries around the world, the C501 has solidified the reputation of CREVOISIER® thanks to its exceptional quality and remarkable reliability.

Even more powerful and smarter

Discover our new C5100 machine which integrates new 4.0 technologies. These allow the saving of recipes, the monitoring of production orders (FO), automatic standby and the reduction of energy consumption. These innovations improve production management, optimize efficiency and contribute to significant energy savings.

Maximize the efficiency of your workspace by combining the power of these machines with the flexibility of our workstations, for impeccable results with every operation.

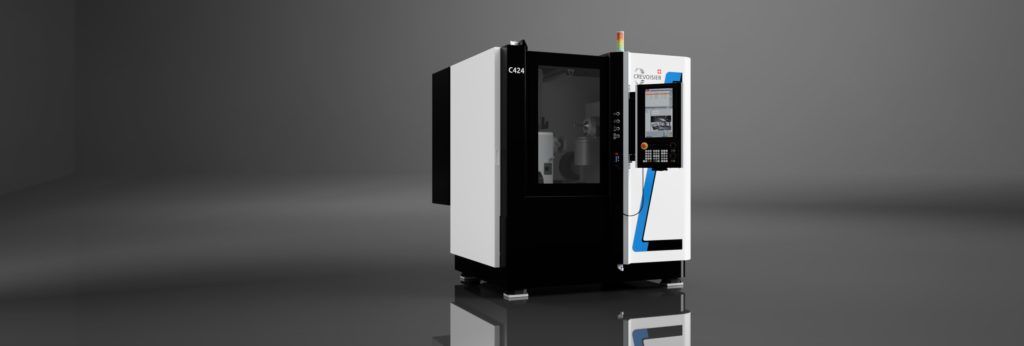

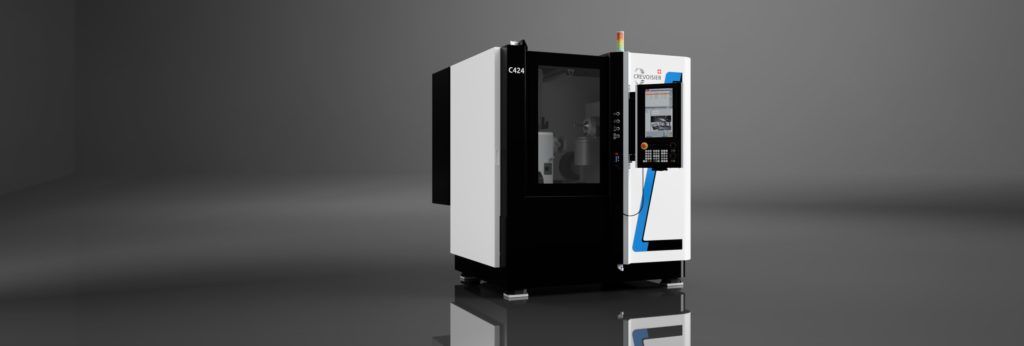

Immerse yourself in the world of performance and versatility, and let yourself be guided through the exceptional features that make our solutions an essential choice for precision machining.

Restez à jour sur les nouveautés Crevoisier!

Crevoisier SA

La Sagne au Droz 7

CH-2714 Les Genevez

T +41 32 484 71 00

F +41 32 484 71 07

info@crevoisier.ch

© 2024 CREVOISIER® All rights reserved. Powered by ivimedia.