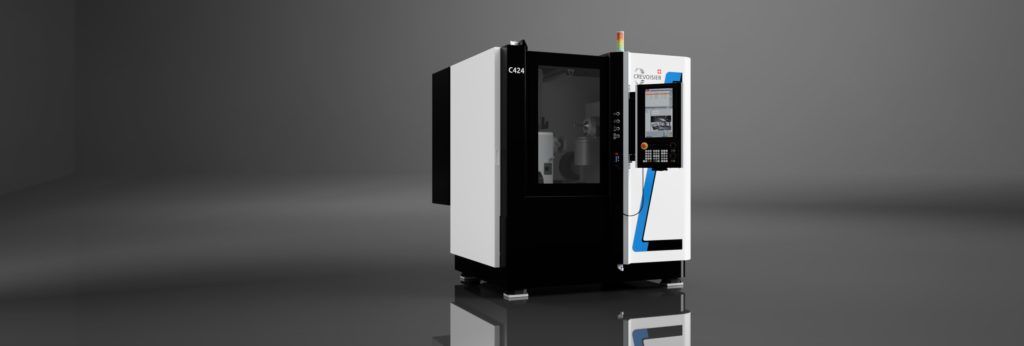

Horizontal lines, slanted digital panel, high visibility and attention to detail for optimal accessibility. The C424 features an avant-garde design and dynamic outline, typical of a Crevoisier® machine.

The functional elegance that characterises the external appearance of the C424 range is also reflected in the ergonomics of its equipment.

All the components are organised rationally, with a design developed to offer you unequalled user comfort.

Drawing on the technologies proven on the C440 and the advantages offered by the brand’s quality standard, the CREVOISIER® C424 is available in 4 different uncompromising versions.

By choosing the right configuration for your needs, you can enjoy a cost-effective solution without compromising on the quality of the parts leaving your production line.

The version A represents the most complete configuration of the C424 range. It is equipped with an HSK 63 spindle operating at 15,000 rpm, fed by a 6-position tool magazine designed for wheels with a diameter of up to 150 mm. In addition, it includes an optional belt device, to enable quick shoe and roller changeovers

The C424B, the successor to the C400B, has retained the same remarkable configuration. Featuring a 4-position turret, it ensures efficient operation of wheels and belt devices, together with an unrivalled tool changeover time. It is important to emphasise that the C400B machine’s programs are fully compatible with the C424B.

The version L is specially designed for lapping, providing a unique two-spindle configuration. This design enables a roughing wheel and finishing wheel to be fitted simultaneously, which can achieve a maximum rotation speed of 6000 rpm.

The version S is identical to the version A in every respect, with the exception that there is no tool magazine. This choice, in accordance with your needs, offers a saving which will further accelerate the return on investment of this production equipment.

The best part price per m2 ratio

The various configurations are built into a single shroud, designed to optimise the workspace and minimise its footprint.

This innovative design enables us to reduce manufacturing costs so as to offer you a fiercely competitive price for your equipment. This solution enables you to produce the maximum number of parts in a minimal space and with minimal investment.

Our machines are equipped with the latest numerical control technologies.

An axes power supply management system recovers the energy released when the axes are braked, and then reinjects it into the machine.

A unit configures the ability to monitor the activities performed on the machine

A remote support solution for the NC facilitates our technical assistance to you (TeamViewer)

CREVOISIER® has developed an interface for linking its C424 and C440 machines to the CAD/CAM systems available on the market.

This software solution enables you to finalise a program, generate the ISO code with the post-processor included in the machine, and create a 3D simulation with the virtual machine.

This completely innovative technology, combined with the simplicity of the machine interface, enables you to reduce down time and optimise the return on your investment.

Our machines are built on a polymer concrete base.

This technology guarantees high rigidity, high thermal stability and excellent damping characteristics, in order to reduce vibrations and ensure higher-quality machining.

Optimal cooling is crucial in the manufacturing process.

Every CREVOISIER® tool holder has its own cooling nozzles. This innovation derived from our research & development department thereby drastically reduces heating, to extend the service life of the consumables and the part cycle times.

Our machines have a long list of assistants to enable you to work 24/7 under numerous situations.

C924 workpiece loading robot – Programmable palletising system – Gripper changing system for machining the 6th face – Automated NC program change – Tool wear compensation – Wheel cutting system with dynamic compensation – Part probing with dynamic compensation, etc.

Immerse yourself in the world of performance and versatility, and let yourself be guided through the exceptional features that make our solutions an essential choice for precision machining.

Restez à jour sur les nouveautés Crevoisier!

Crevoisier SA

La Sagne au Droz 7

CH-2714 Les Genevez

T +41 32 484 71 00

F +41 32 484 71 07

info@crevoisier.ch

© 2024 CREVOISIER® All rights reserved. Powered by ivimedia.

Ce site utilise des cookies à des fins de statistiques, d’optimisation et de marketing ciblé. En poursuivant votre visite sur cette page, vous acceptez l’utilisation des cookies aux fins énoncées ci-dessus