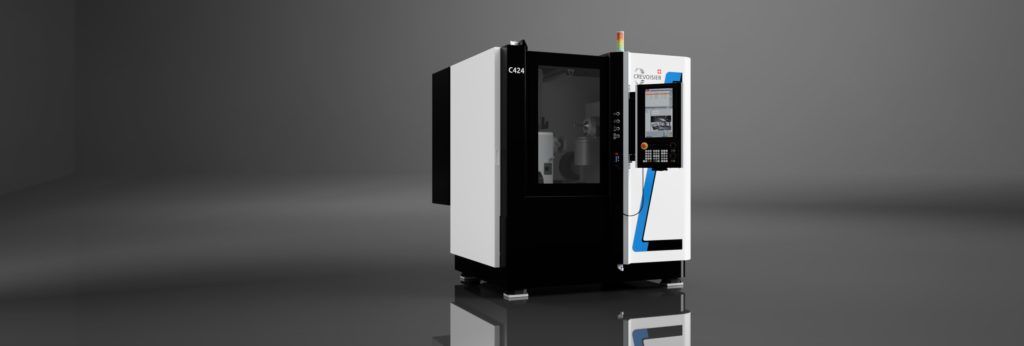

The C606 is a configuration derived from our CREVOISIER® C600 rotary transfer decorating machines range.

These machines, developed for decorating watchmaking components, can be equipped with 2 to 6 workstations, depending on the number of operations to perform on the components.

Les machine de transfert CREVOISIER® C600

sont équipée d’une table rotative de haute précision avec 2 – 6 positions.

Modularity

The equipment has a considerable degree of modularity. There are several installation configurations available on the same basic machine. The configuration will vary in line with the chosen operation.

According to the application, we can create a customised new configuration. In addition, CREVOISIER® develops tooling according to the requirements of the parts and decorations.

The C axis developed entirely in-house by CREVOISIER® SA

Already proven on various CREVOISIER® machines, the C axis comes with a built-in rotary encoder for position and speed checking.

The System 3R interface provides flexibility in quick clamp changeovers.

Range of fixtures available

The parts are positioned by pins and recesses, and can be held during machining by means of a vacuum.

To facilitate loading / unloading, extractors can be added as an option.

CREVOISIER SA develops tooling according to your needs and the production requirements.

– Circular softening

– Lengthwise softening

– Snailing

– Brushing

– Felt polishing

– Etching

– Chamfering

– Micro-milling

– Diamond polishing

– Others on request

– 4 interpolated CNC axes (or more according to configuration)

– Measurement ruler on all the axes

– 3600 min-1 clamping spindle with encoder

– 2 to 6-position rotary table, as required

– Concurrent manual loading

– Palletised parts loaded by the robot

– Loose workpieces loaded via a vibrating bowl or hopper

– Robot unloads and palletises

– Part presence check

– Dust and residue cleaned from work area by suction

– Specific fixtures and vacuum

– Fire protection system

Example for C607 version

Height 2710 mm

Width 2910 mm

Depth with cooling spray tank 1905 mm

Weight ≈ 1500 kg

Restez à jour sur les nouveautés Crevoisier!

Crevoisier SA

La Sagne au Droz 7

CH-2714 Les Genevez

T +41 32 484 71 00

F +41 32 484 71 07

info@crevoisier.ch

© 2024 CREVOISIER® All rights reserved. Powered by ivimedia.

Ce site utilise des cookies à des fins de statistiques, d’optimisation et de marketing ciblé. En poursuivant votre visite sur cette page, vous acceptez l’utilisation des cookies aux fins énoncées ci-dessus