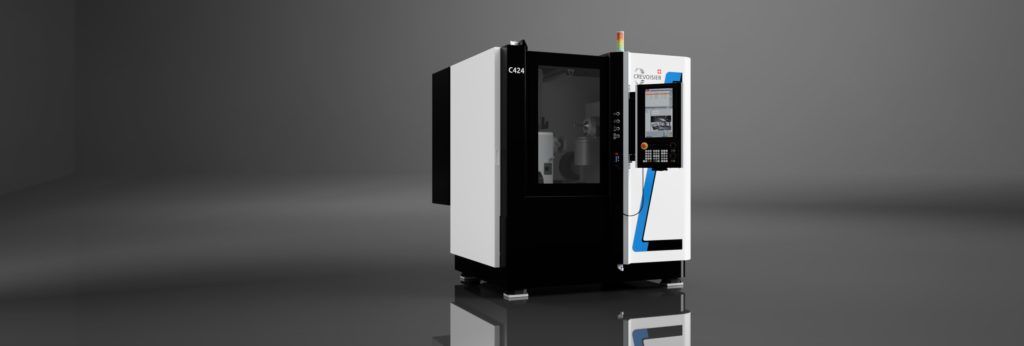

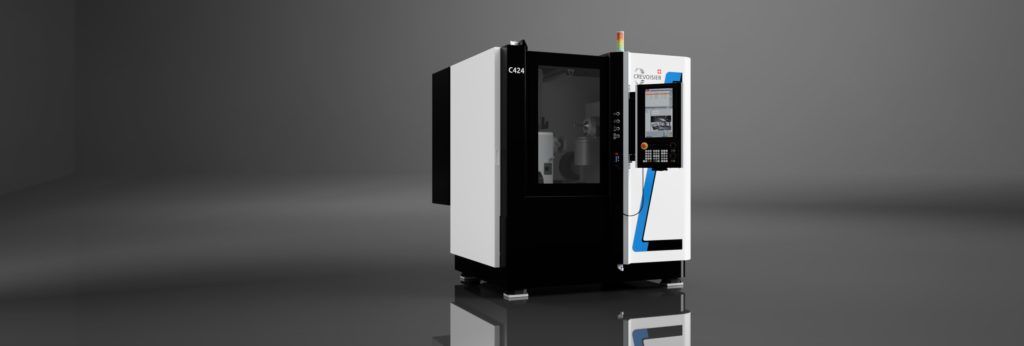

The versatility of the CREVOISIER® C440 grinding and finishing centre gives you a considerable advantage to stand out from your competitors, and gain market share.

The C440 machine boasts excellent dynamism, thanks to the robustness of the mineral cast iron frame.

This technology guarantees high rigidity, high thermal stability and excellent damping characteristics, in order to reduce vibrations and ensure higher-quality machining on both soft materials and hard ones such as ceramic, carbide or sapphire.

Our machines have several solutions enabling you to work round the clock.

Programmable palletising system – Gripper changing system for machining the 6th face – Automatic multiple reference manager – Automated NC program change

Measurement and compensation

Tool probing with wear compensation – Wheel cutting system with dynamic compensation – Wart probing with dynamic program correction.

• Powered spindle fitted with HSK-E63 fixture; 200 to 15,000 min-1, 18 Nm

• 12-position tool changer (wheel dimensions: max. ø 250 mm, width 60 mm).

• Multi-tool spindle, 8-position HSK-E25, 50,000 min-1

• Horizontal or vertical 100×1500 belt, shoe or 3R© base-mounted roller devices.

• 4-position comb for the turning chisels

• One 3D part probe

• 1 tool probe

• Reworking option for machining the 6th face

• Polyarticulated robot for workpiece loading

• Various configurable palletisers

• Standby mode and energy recovery system

• Milling

• Drilling (with or without accessories for straight and angular inter-horn area)

• Etching

• Turning

• Diamond polishing

• Guilloche finishing

• Grinding

• Emery grinding

• Linear and circular satin-finishing

• There is a vast tooling catalogue available.

• We will create the clamping system according to your application and the complexity of the part to be machined.

• Our tooling, guaranteeing you savings and flexibility, is compatible with all your C480, C440, C424 and C400 machines.

• Main cooling spray 14 bar, adjustable flowrate 30-60 l/min,

• Independent cooling nozzles on each tool holder for optimum setting.

• Central cooling spray on multi-tool system.

• 400-litre tank, cooled for greater stability.

• 5 μm absolute filtration with no consumables, excellent waste collection and flawless oil quality.

• Bypass for working on two types of materials without needing to clean the tank and filtration system

• Can be linked to a central unit.

• 6.1 m2 with the loading robot and C910 palletiser

• 8.3 m2 with the cooling tank in addition to the loading robot and C910 palletiser

• Height 2480 mm, or 2820 mm with cooling spray tank

• Axes travel:

X axis 538 mm, 40 m/min

Y axis 319 mm, 40 m/min

Z axis 497 mm, 40 m/min

B axis ±135°, 780°/s

C axis 360°, max. speed 2000 min-1

V axis ±180°, 780°/s

Our expertise at your disposal

We offer complete turnkey solutions to meet your manufacturing needs. Our comprehensive approach encompasses clamp system design, to guarantee optimal fixture for every application. On top of that we customise the operating procedure to ensure maximum efficiency, taking into account your quality requirements. Furthermore, we optimise cutting speeds according to the tool-material pair, to ensure peak performance and a longer tool service life. With our turnkey service, you have a perfectly tailored solution, combining precision, productivity and ease of use.

The machine is delivered with a programming software (Shop Floor Programming SFP). This enables you to optimise and make 3D simulations of your programs, with an active anti-collision solution. This solution also enable you to retrieve the 3D files and trajectories programmed on any CAD/CAM system on the market, to optimise the programs and eliminate any post-processor errors.

HMI pages are also included, to enable you to modify the operation parameters at the base of the machine.

There are several solutions enabling you to work round the clock with our machines, e.g. our various CREVOISIER® C910 and C920 loading cells, which come with built-in gripper change, wheel re-buffing and a turnover station enabling you to autonomously manage several WOs comprising different parts quantities and programs.

hanks to our machine axes power supply management system, the energy generated during braking is reintegrated into the machine, thereby creating a continuous, self-sustaining power supply cycle. If an electricity surplus is recovered, it is redirected to the electrical network.

Furthermore, our standby mode, which fully disables consumption by the machine and its units when production has stopped, ensures significant energy savings. This proactive approach contributes to optimising energy efficiency and minimising costs, making our solution an eco-responsible choice.

Immerse yourself in the world of performance and versatility, and let yourself be guided through the exceptional features that make our solutions an essential choice for precision machining.

Restez à jour sur les nouveautés Crevoisier!

Crevoisier SA

La Sagne au Droz 7

CH-2714 Les Genevez

T +41 32 484 71 00

F +41 32 484 71 07

info@crevoisier.ch

© 2024 CREVOISIER® All rights reserved. Powered by ivimedia.

Ce site utilise des cookies à des fins de statistiques, d’optimisation et de marketing ciblé. En poursuivant votre visite sur cette page, vous acceptez l’utilisation des cookies aux fins énoncées ci-dessus