Ultra compact (1 meter wide x 2 meters deep) CREVOISIER® C48 is distinguished by its dynamic and modern silhouette.

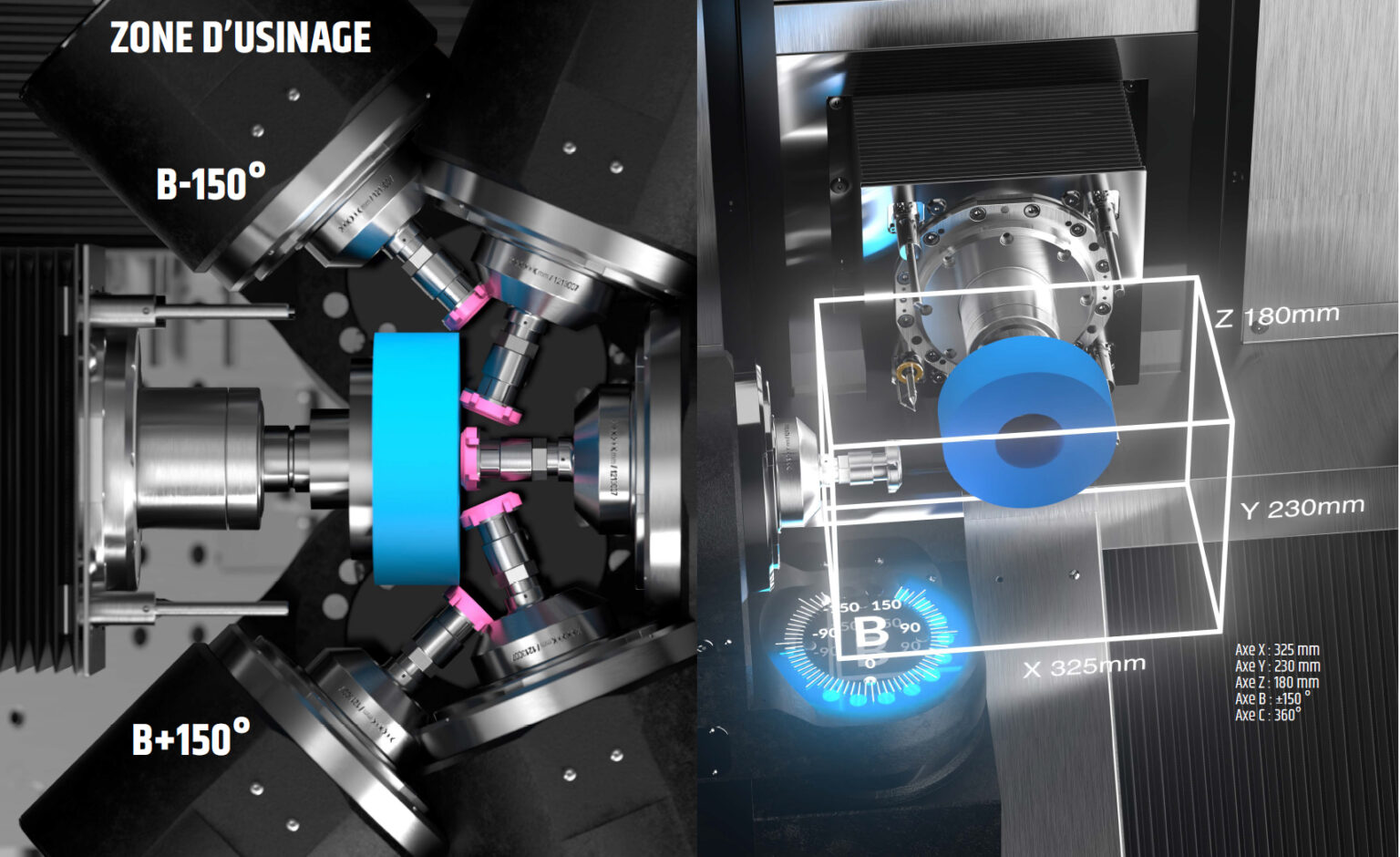

The simultaneous 5-axis kinematics allows grinding, milling, drilling and decorating operations for the watchmaking, jewelry, medical and mechanical fields.

Designed with extreme robustness, it excels in materials such as steel, stainless steel, precious metals, titanium, sapphire, ceramic and even carbon.

Despite its reduced size, we have achieved the feat of freeing up an enormous machining area of:

X325 mm x Y230 mm x Z180 mm with a rotation B of ±150°

Dimensions: 1000 mm width x 2000 mm depth x 2300 mm height

Electrical voltage: 3 x 400 V – 50 HZ

Electrical voltage: 3 x 400 V – 50 HZ

Mains fuses: 20 A at 400 V

< < 5 bars

Weight: Approx. 2,900.kg

Axis travels:

X axis: 325 mm Max speed: 3m/s (180m/min)

Y axis: 230 mm Max speed: 3m/s (180 m/min)

Z axis: 180 mm Max speed: 3m/s (180m/min)

The compact grinding center, offering the largest machining volume on the market.

Our machines are equipped with the latest digital control technology.

An axis power management system makes it possible to recover the energy released when the axes brake, to reinject it into the machine.

A box configures the capacity to monitor the activities carried out on the machine.

A remote control solution for the CNC allows us to facilitate our technical assistance (TeamViewer).

CREVOISIER has developed an interface which allows the C48, C424 and C440 machines to be connected to CAD/CAM machines on the market.

This software solution allows you to finalize a program, generate the ISO code with the postprocessor included in the machine and simulate the code in 3D with the virtual machine.

This completely innovative technology, combined with the simplicity of the machine interface, allows you to reduce non-productive time and get the best return on your investment.

On our machines, the list of assistants is long to allow you to work 24/7 in many situations.

Parts loading robot C924 – Programmable palletizing system – Gripper changing system for machining the 6th face – Automation of NC program change – Tool wear compensation – Grinding wheel cutting system with dynamic compensation – Part probing with dynamic compensation, etc.

To absorb large production volumes, it is possible to connect several C48 cells together with intermediate stations which have robots for transferring parts or fixtures. These connections make it possible to integrate, for example, a means of control and/or a cleaning system, to ensure the smooth running of the manufacturing process.

Restez à jour sur les nouveautés Crevoisier!

Crevoisier SA

La Sagne au Droz 7

CH-2714 Les Genevez

T +41 32 484 71 00

F +41 32 484 71 07

info@crevoisier.ch

© 2024 CREVOISIER® All rights reserved. Powered by ivimedia.