Description

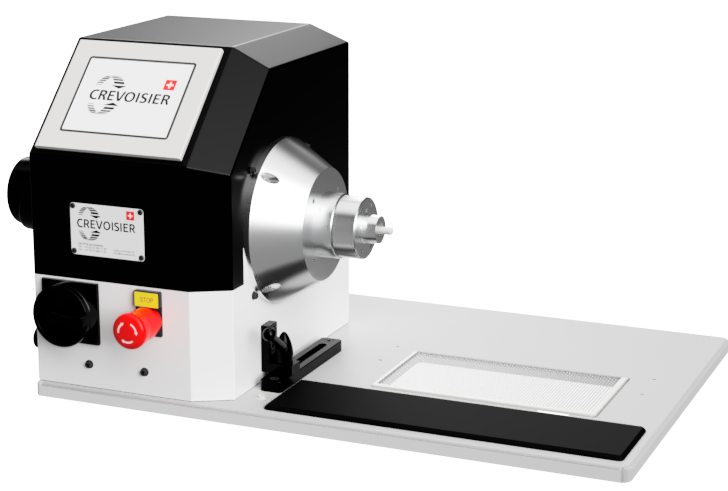

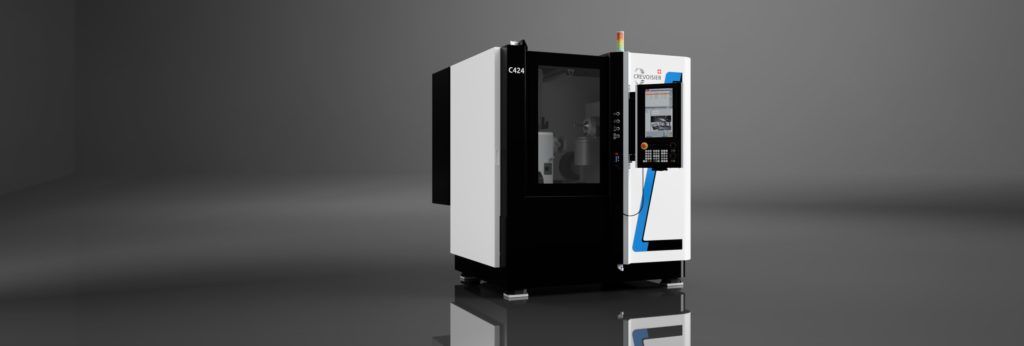

The C5001 : Polishing, lapping and satin-finishing – All in one machine!

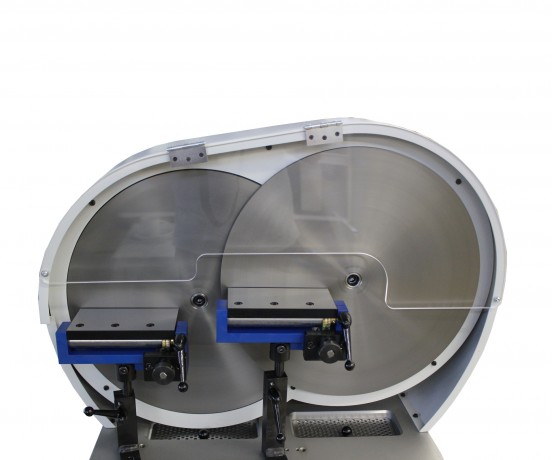

The C5001 universal finishing machine can be used for polishing, buffing, satin-finishing, lapping and many other preparation and finishing operations. This latest generation machine is equipped with a spindle motor and a touchscreen providing an intuitive user interface.

This machine is used in the production units and After-Sales centres, and also the training schools. Available for workbench or station installation, with built-in suction.

Showcase your know-how with the C5001 ECO KIT machine: Performance in your hands!

Uncompromising

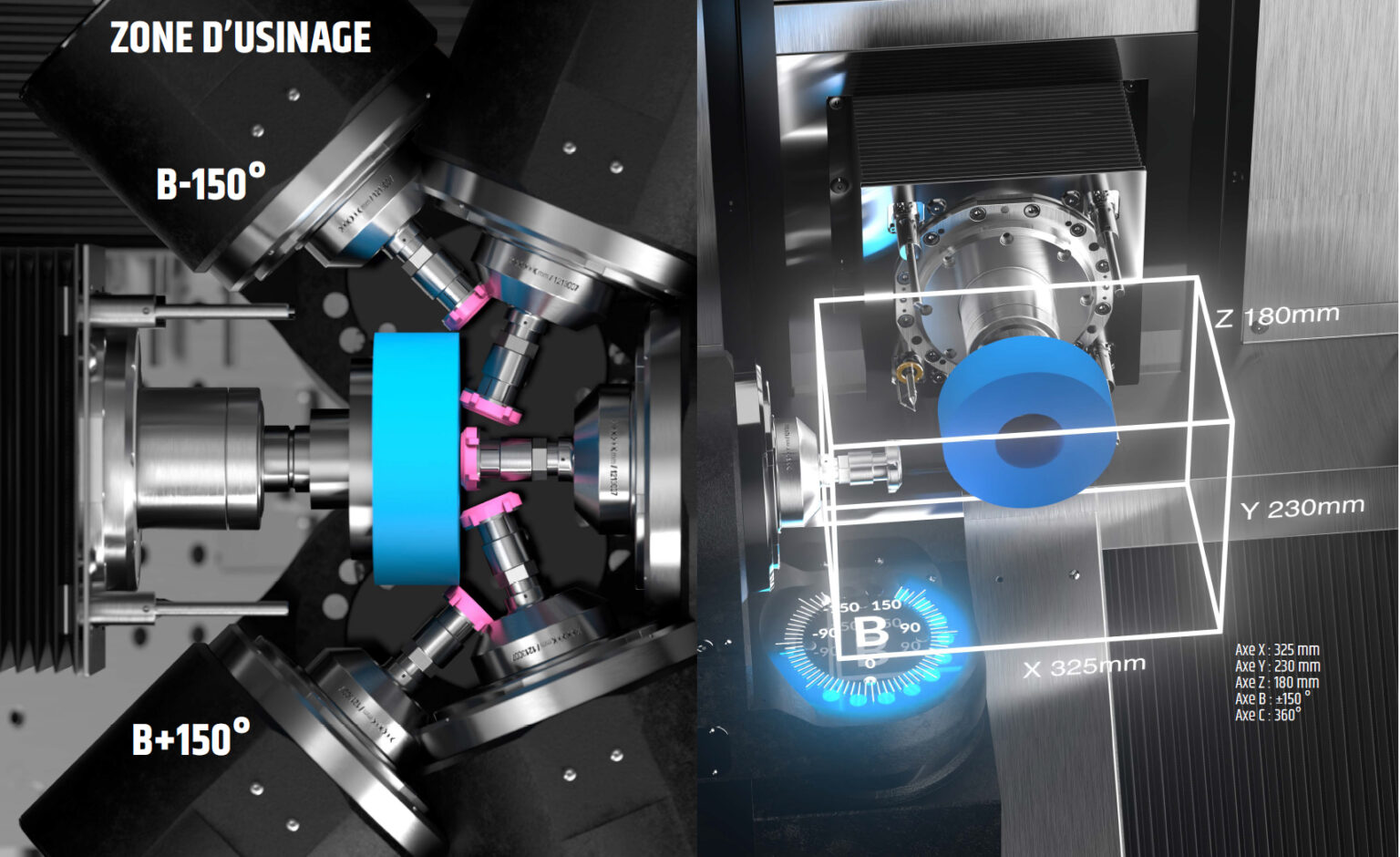

Our machines stand out for their exceptional performance, providing a more accessible way to achieve high-quality parts. Thanks to its unrivalled precision, our equipment can more readily achieve the most stringent standards in terms of quality. Investing in our technology will not only guarantee you increased productivity, but also the certainty of obtaining exceptional quality parts, meeting the highest requirements.

Technical specifications

C5001 machine

- Spindle motor with hardened and ground nose

- Compatible with CREVOISIER® tooling range

- Anodised aluminium base plate for mounting various accessories (table, lapping bar, etc.)

- Adjustable depth and working height

- User-friendly interface thanks to the high-definition touchscreen

- Rotation speed range adjustable from 100 to 6000 min-1 (2-way rotation)

- Speeds storable on the machine itself, or exportable

- Manual and automatic emergency stop by overvoltage control on the spindle

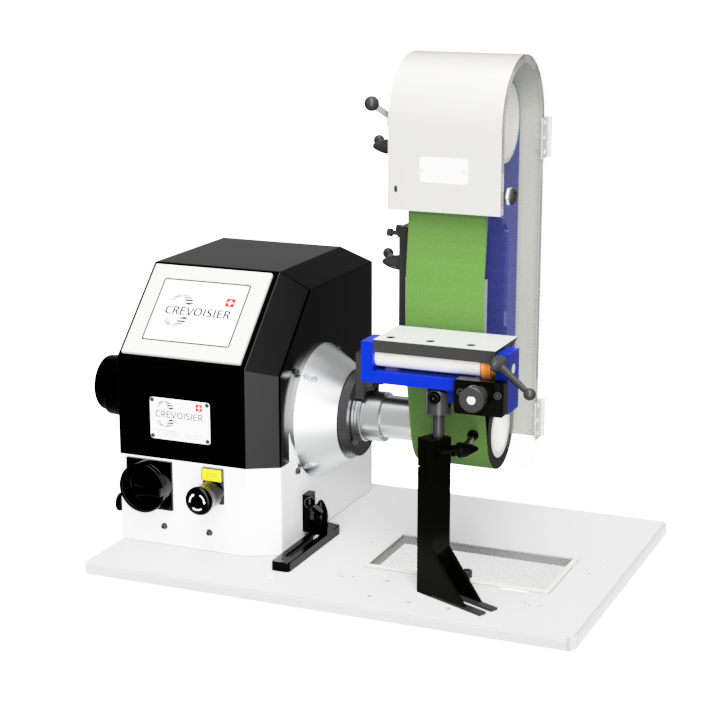

- Vertical satin-finishing with table (bobino)

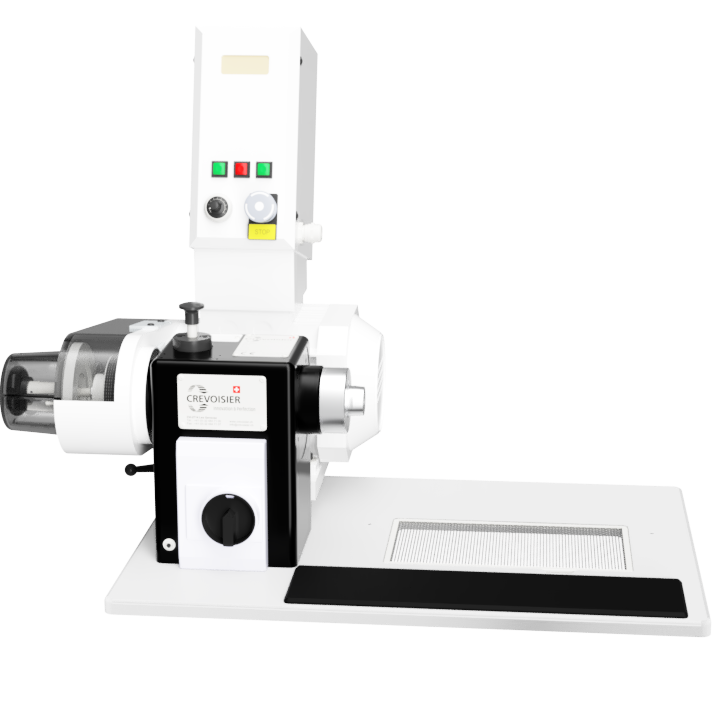

- Polishing

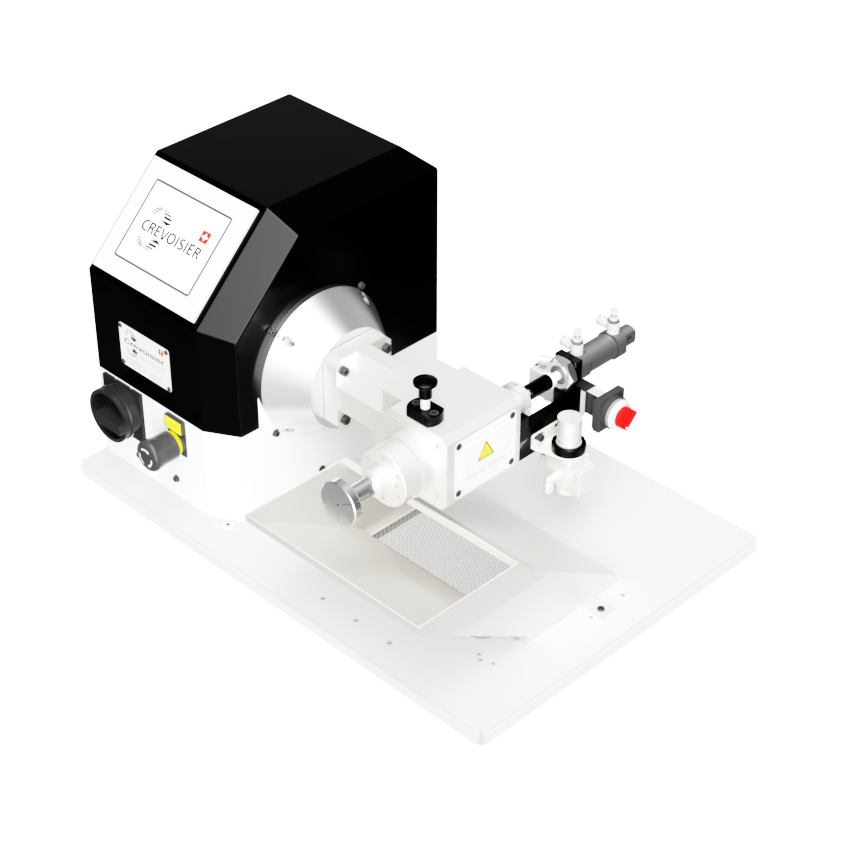

- Lapping with table

- Lapping bar with lapping carriage

- Frontal lapping

- Double lapping with table

- Double lapping with lapping carriage

- Vertical satin-finishing

- Vertical satin-finishing with table

- Roller satin-finishing

- Vertical satin-finishing with belt guide

- Horizontal satin finishing

- Circular satin finishing

- Dimensions: L640 x D440

- Centre point height 170 mm (optionally 200 or 220 mm)

- Weight: approx. 60 kg

OPT FOR A CUSTOMISED, QUIET WORKSPACE

Fit your machine on an ergonomic station

Our C5001 ECO KIT machine is perfectly adaptable to our polishing stations, and comes with an ultra-quiet built-in suction and filtration system.

With this combination, you can make big energy savings and create a customised workspace meeting your specific needs and enabling you to increase your productivity. Come and explore the options available, and discover how the synergy between our machine and the DSG stations can revolutionise how you work.

Video

The C5001 universal finishing station is used for polishing, buffing, satin-finishing and lapping operations, and many other preparatory and finishing jobs.